When performing cladding works, a tile leveling system may be necessary for the best tile leveling system. There are many different opinions about such innovation, both positive and negative since many people are interested in the question “what is the tile leveling system for”.

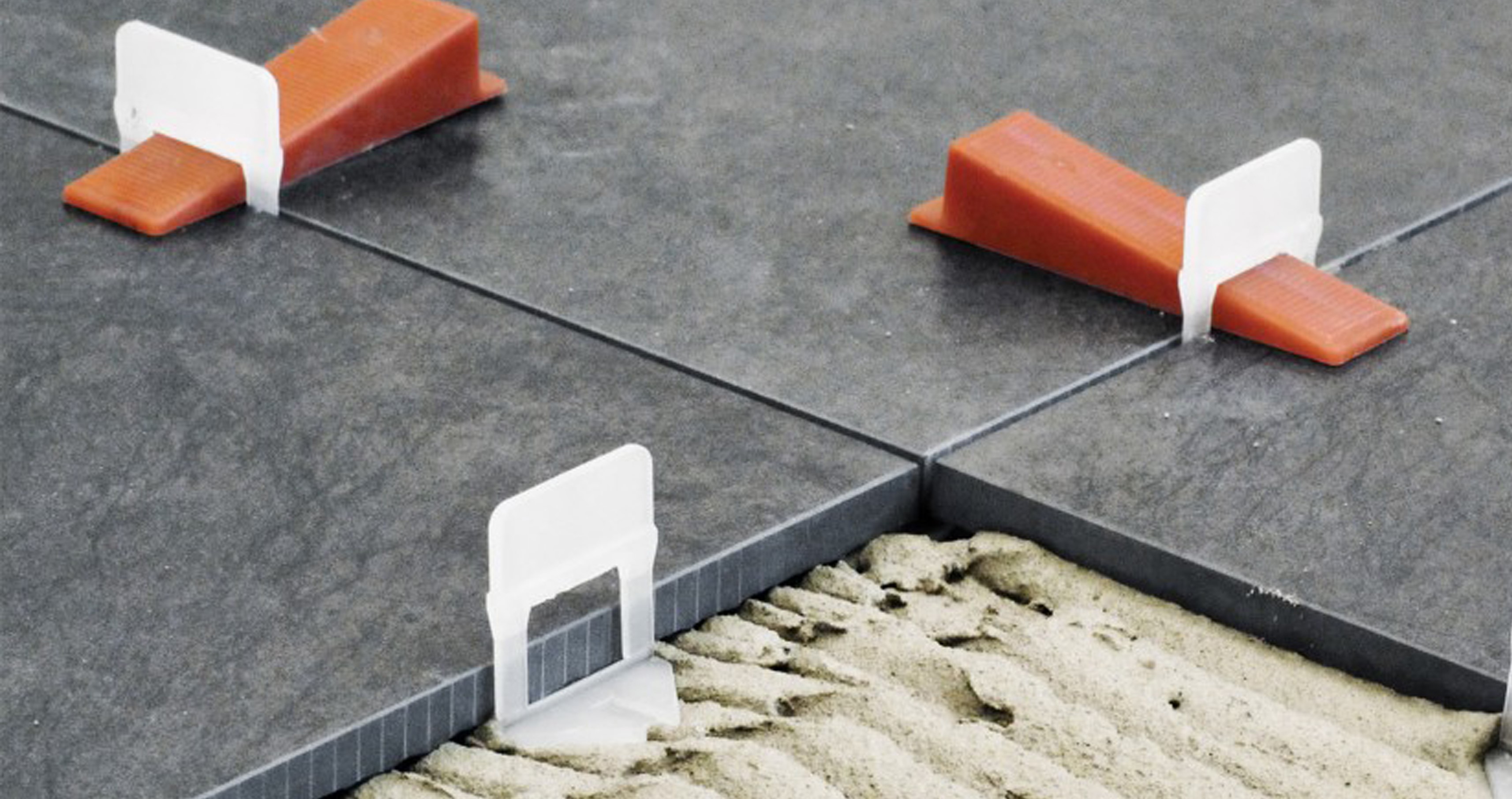

But to figure it out and understand what makes the tile leveling system the best for yourself. Tile leveling system uses used for independent tile laying. It was designed to facilitate the task of masters in obtaining an ideally equal level of laying surface. In essence, such a system is the replacement of plastic crosspieces for seams. It has a kind of wedges with clamps, consisting of two parts. The basis is wedge-spacers, which regulate the position of the tile relative to the neighboring parts. However, to get real benefits from these wedges, their position must be fixed using the wedges of the clamps. So the tiles are exposed to a position that eliminates the differences in height, distributing the glue under the coating with a uniform layer. In other words, the tile leveling system averages the position of adjacent tiled products, allowing you to achieve an ideally flat surface when laying tiles.

Using the tile-leveling system: its key benefits and disadvantages.

The system used to align the enclosing tile has already earned the recognition of many professional craftsmen, although there are those who continue to reject its expediency, considering it not only useless even complicating the staging process. Therefore, it is better to study all its advantages and disadvantages beforehand.

Advantages of the tile alignment system are as follows:

- Equal floor, since using the system you can set the optimal floor level. This affects both the quality and appearance of the masonry and increases the life of the coating. It is much easier and faster with such an adaptation than using traditional methods;

- The presence of identical seams. The basis of the system is placed between the tiles, thus, it is a good replacement for the usual plastic crosses. At the same time it is possible to fix the exact distance between the parts, which is the same throughout the processing area;

- Tile adhesive is evenly distributed. If the floor does not have an ideal surface, then this disadvantage can be leveled by the optimal distribution of the composition of the glue. So all voids are filled with a solution that is distributed over the plane if it has projections. This is especially true for cases where it is necessary to apply glue with a thick layer because it is very difficult to perform such a job manually;

- The tile leveling system prevents the tiles from falling. Even after drying of the treated surface, the floor will maintain its level, without falling from the loads on it;

- The tile leveling system fixes the tile during drying. Typically, in the process of drying the tile can change its initial position, and more specifically jump on the edges, shift, and sink. These disadvantages are eliminated by clamps that tightly tilt the tile to the base and fix it in this position until the moment of removal of fasteners.

The tile leveling system consists of the following:

- time spent on the installation of wedges and their further removal;

- difficult to clean seams;

- you have to foresee additional expenses for the purchase of the system itself.

There are some differences between these species. The standard tile leveling system is used in most cases if there are no significant fluctuations on the surface of the cladding. In this case, the base element has a straight foundation and is pressed from the top by a wedge, thus fixing the position of the tile, exposing the same joints and smoothing the small inequalities.

Tile leveling system premium class apart from the high price and special features. First, it is easily distinguished by its specific structure, since the basis of the interlayer insert is a curved shape. This may seem at the beginning rather than a disadvantage of such a product, causing even surprise. However, even though the foundation initially shifts the tiles, after it is fixed with a clamp, self-alignment will occur. The plate will be aligned exactly as long as it is required for the even placement of the tile and the distribution of the glue in relation to the existing inequalities on the floor surface.

Using the tile leveling system is as follows:

- The adhesive is applied to the floor surface with a toothed spatula;

- The first tile is attached. Under the tile is installed on two clamps on each side, retreating from its edge about 4 centimeters;

- Put a second tile;

- A wedge is inserted between the top of the clamping plate and the tiles, which is fixed so that its lower part tightens to the tiles while aligning the sides of the tiles;

- The clip is tightened until it is fixed tight;

- The seams are cleansed of the resulting adhesive mixture, without breaking the position of the tiles. If you do not clean the glue on the seams of the tiles, it will be difficult to remove it after drying, which will also affect the strength of the coating;

- To remove the wedges after drying the adhesive solution, you just need to hit the top of the clamps along the tile seam;

- The bottom of the clip is left under the tile;

- The degree of the need for a tile alignment system is determined by each master for himself. To obtain an absolutely smooth surface, you should use all available methods for this;

- Of course, the use of such wedges also does not exclude application in the construction level, since it depends on it the final quality of the surface obtained;

- The end result also depends on the quality of the purchased tile, so if the product will be curved, then achieving an even surface is unlikely to succeed. Thus, the end result will depend on the smallest factors. More often, in order to obtain ideal, vertical and horizontal gaps, apply a level for laying ceramic or tile tiles. This device is a metal plate, a durable thread, and a curved semi-perimeter. In this case, the thread helps to remove the plates from the dried adhesive composition for the tile.